Germ Fresh supplies plant-treated air to patient rooms when it’s desirable

It is well known that environmental contamination significantly increases healthcare-associated infections (HAIs), a major cause of mortality in patients. Infections are promoted by airborne pathogens and by direct contact between patients, healthcare workers, and contaminated surfaces. So we asked a simple question. Can we reduce HAI pathogens by introducing other microorganisms into hospital environments? That is to say, can we remove some germs by adding other germs?

Initially, this tactic may seem counterproductive, however recent research showed that the approach deserved further inquiry. The average person sheds 37 million bacteria every hour. Mechanical systems gather and redistribute these microbes, causing a greater concentration of potential pathogens than one would find in patient rooms with open windows. Mechanical systems essentially manage and produce human microbiomes, whereas natural ventilation introduces greater bacterial diversity from plants, a benefit to human health. So we studied how we could create a diversified microbiome in hospital patient rooms.

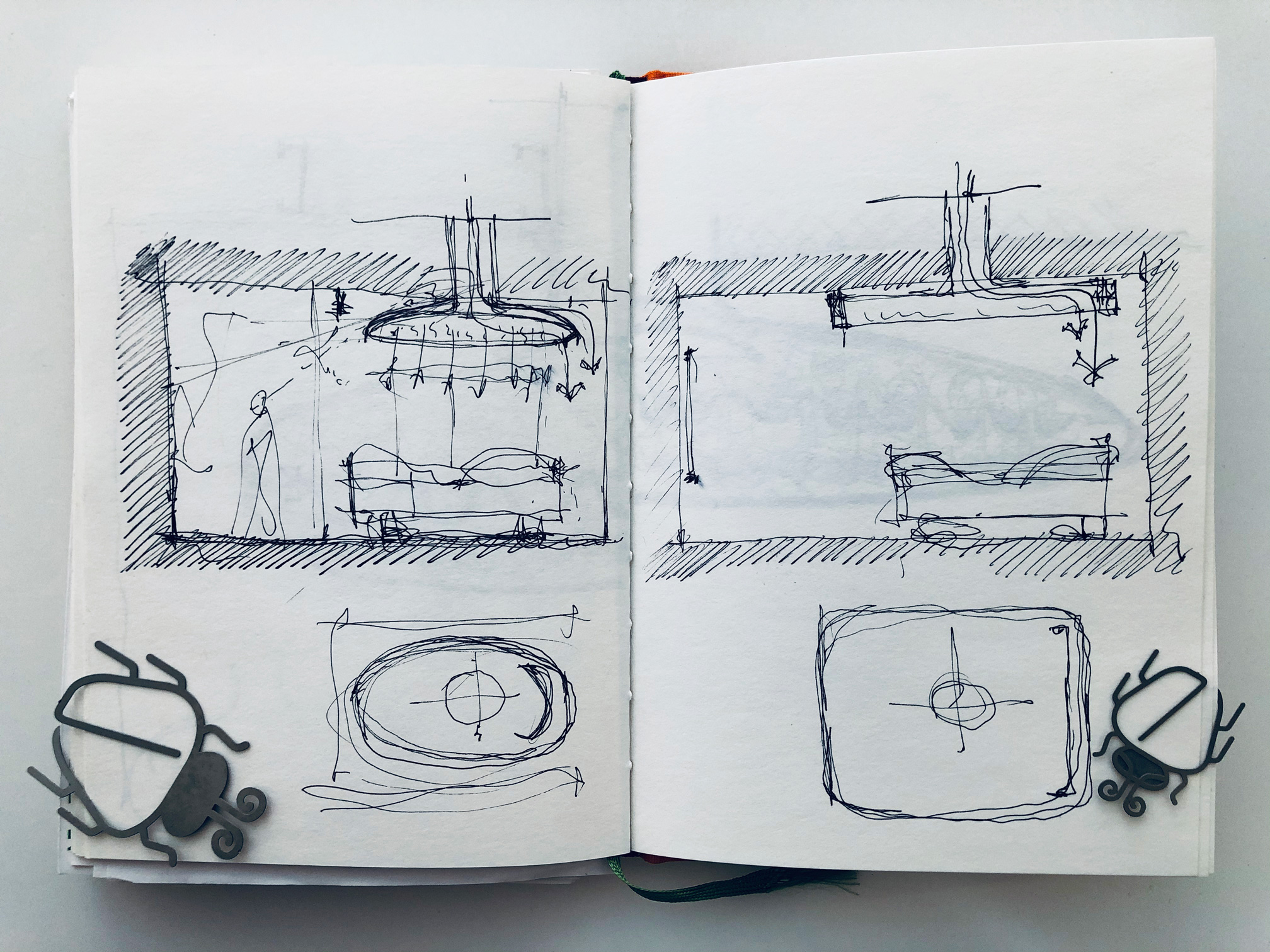

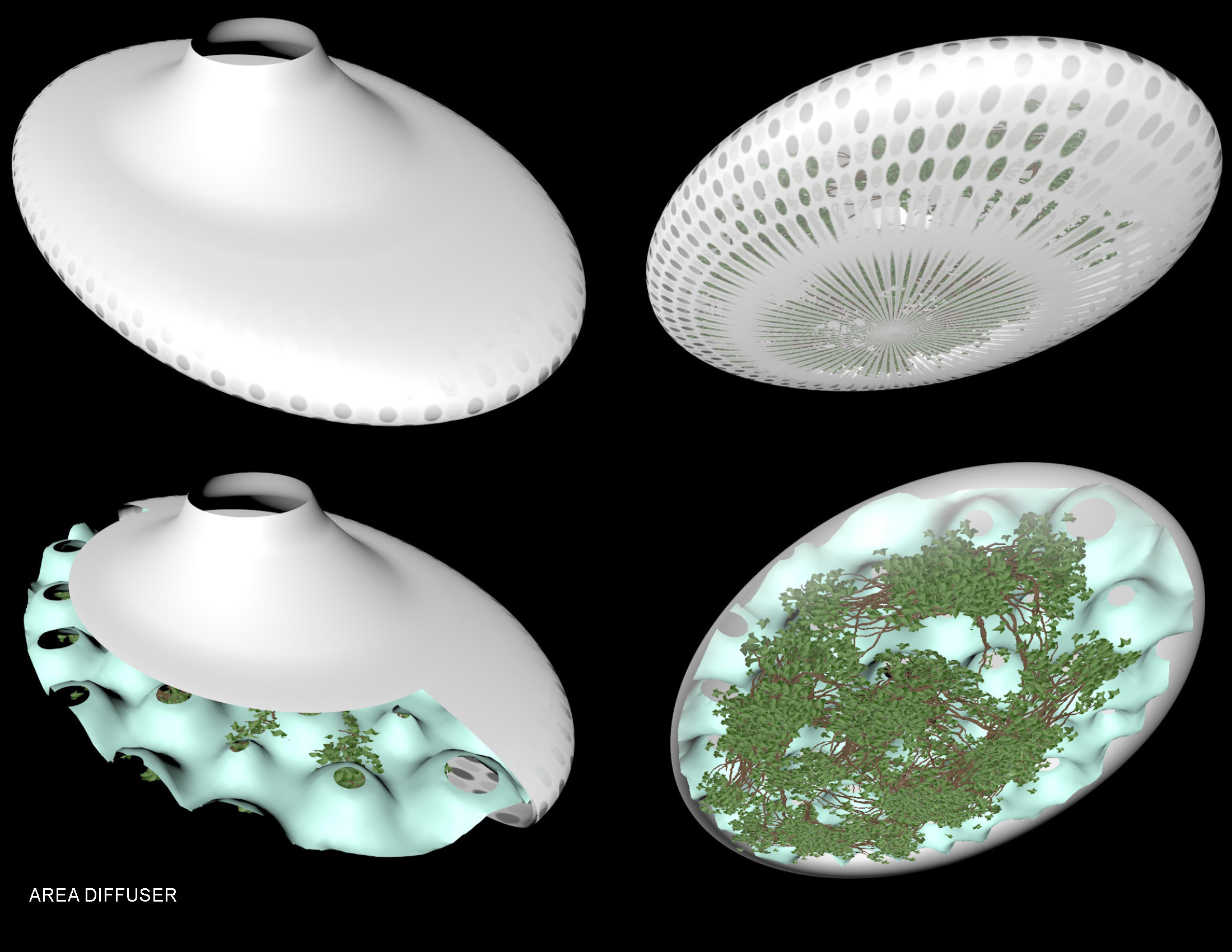

Schematic design for an HVAC diffuser, showing air flow for plant-treated supply air

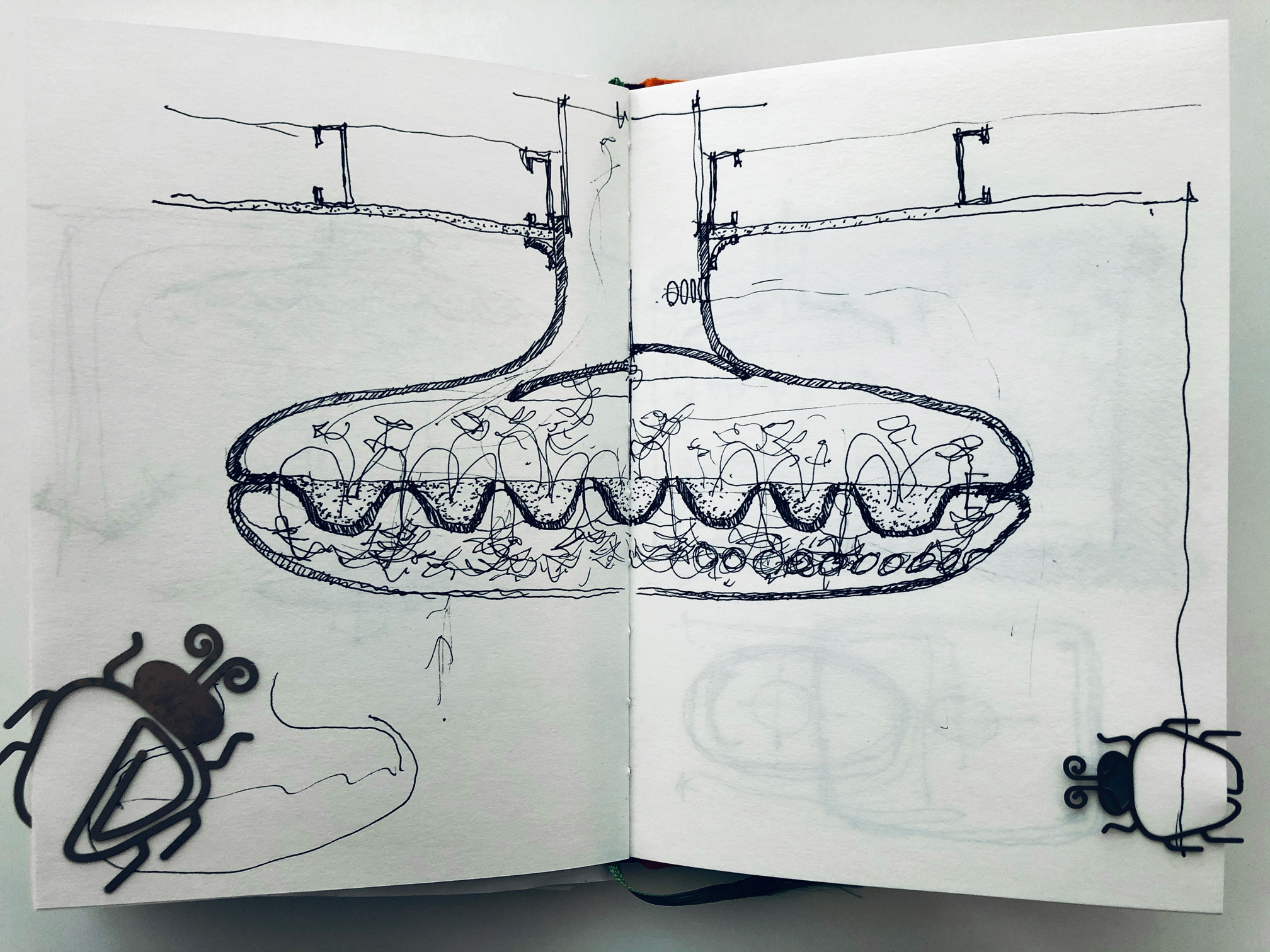

The result of the study was GERM Fresh, a new, controllable means of introducing plant-treated “fresh” air into highly regulated hospital environments. Our redesign of an HVAC supply air diffuser permits air to circulate through plants that are living within the diffuser, before it flows into the room. Alternatively, when that’s not desirable, the air flow can be diverted away from the plants, upstream, and delivered into the room as purely mechanical air. A controlled mixture of the two is also possible, depending on the needs of the occupants in each room.

Schematic design for an HVAC diffuser, showing air flow for untreated supply air

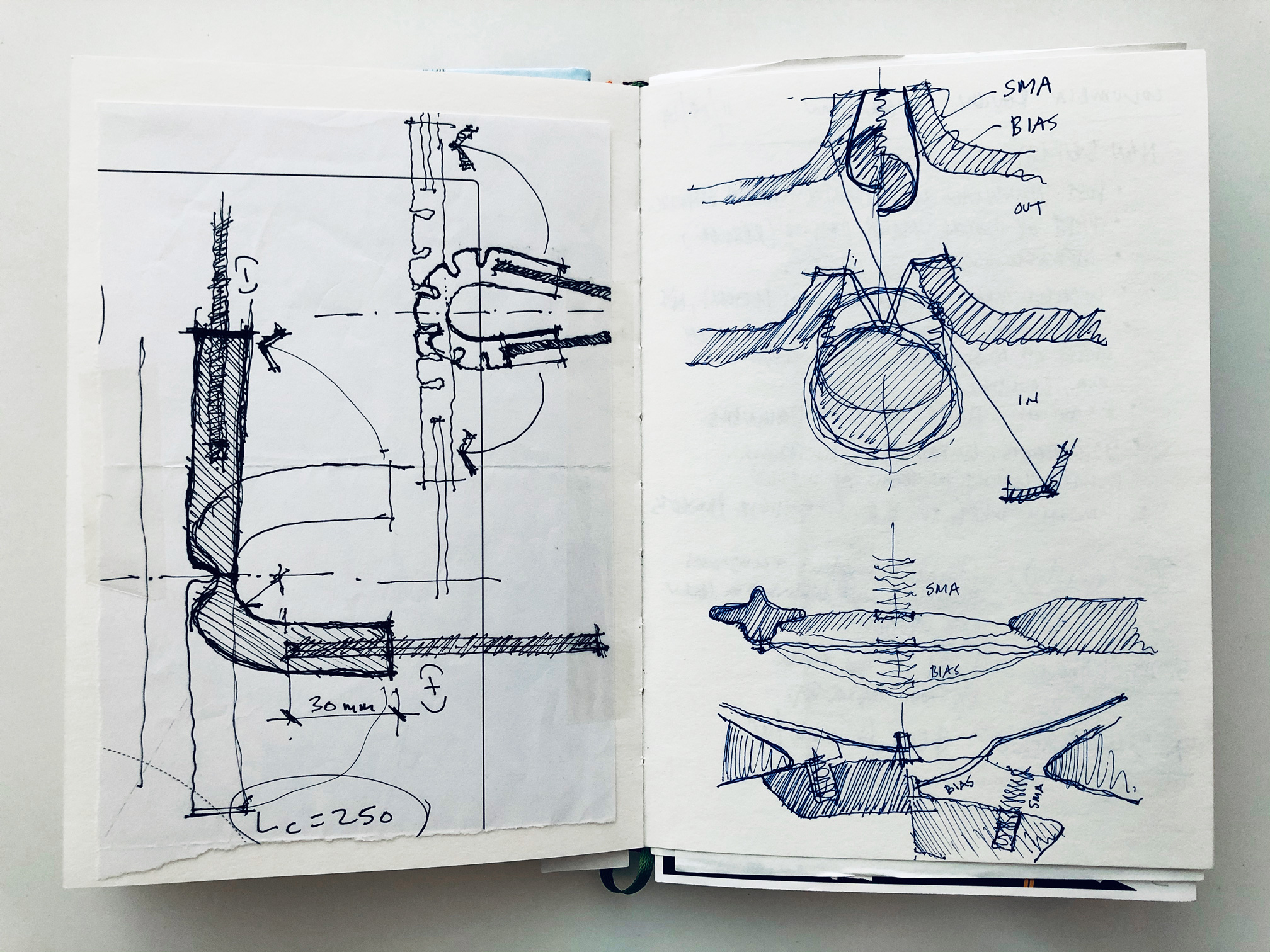

The project considered: basic airflow, general plant type, the need for a hydromembrane for growing plants inside the diffuser, plant irrigation, structural support, integration with conventional ceiling systems, maintenance access, full spectrum lighting for the plants, air dampers and control, manufacturability and ease of assembly, and site installation. We did not redesign the other parts HVAC systems, which would likely remain the same.

The physical form of the diffuser, coupled with the position of the light, would encourage the plants to grow in a particular direction, downward. We identified some possible plants that might be appropriate for the project, including Devil’s Ivy (Epipremnum aureum). A NASA clean air study confirmed that it is one of the best plants for removing indoor pollutants (e.g., formaldehyde, xylene, toluene, and benzene), and for mitigating sick building syndrome. We also like this plant because it stays green in appearance, and doesn’t consume much water, but air plants could also be advantageous.

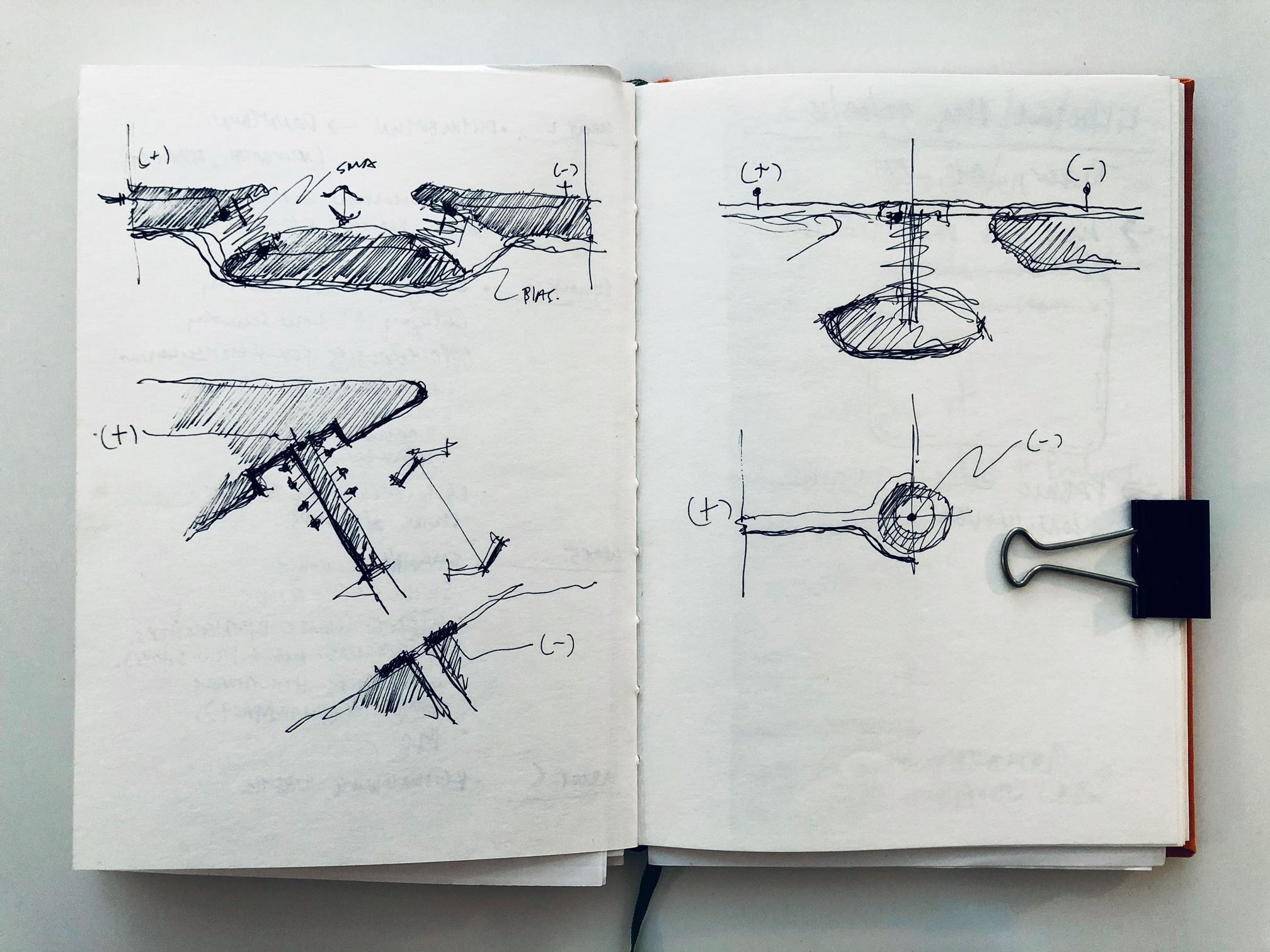

We reshaped and optimized the design after meeting with hospital ventilation specialists, and by using simulation software and particle emitters to visualize airflow within (and around) various diffuser designs. Whenever airflow was less predictable, it was important to create simulations to show: 1) how supply air passed through the diffuser, 2) how the air migrated through the plant chamber within the diffuser, and 3) how mechanically-treated supply air might avoid the plant chamber but still be effectively diffused into the room.

Peer review with architects, engineers, and medical professionals revealed some critical challenges with the main premise of the project, but also produced a number of recommendations regarding new directions the work might take.